UV Film vs. Blue Film: What’s the Difference in Wafer Dicing

In semiconductor manufacturing, wafer dicing is a crucial step where processed wafers are cut into individual chips. To protect and hold the wafer in place during this high-precision cutting, a special adhesive film—known as dicing tape—is applied to the back of the wafer.

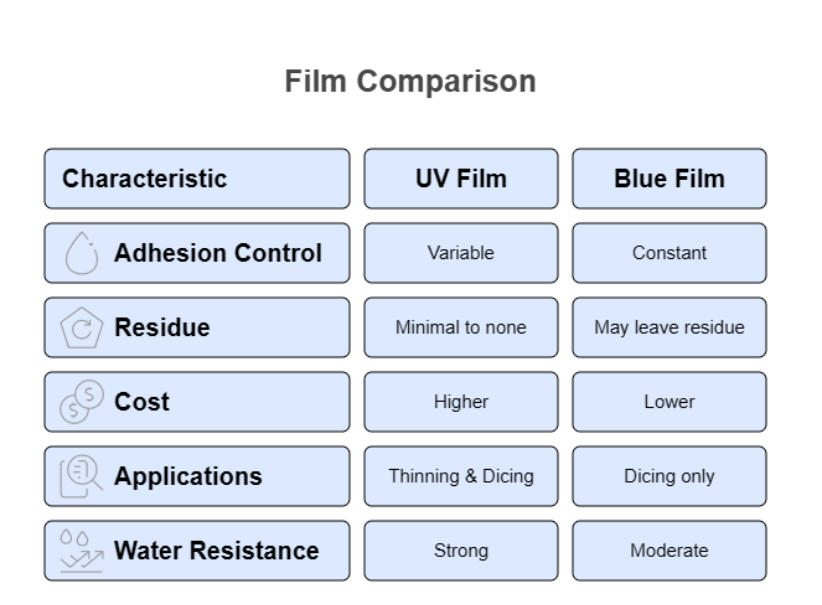

In actual production, the film used to fix wafers and chips generally uses UV film or blue film.

UV film: mainly used in wafer thinning process;

Blue film: mainly used in wafer dicing process;

UV Film

.Changes stickiness after UV light exposure

.Strong hold before cutting, easy release after

.Leaves no residue

.Ideal for thinning and dicing

.Higher cost, shorter shelf life

Blue Film

.Constant stickiness

.More affordable

.May leave residue, especially with heat

.Used mainly for dicing

Choosing the Right Tape

Selecting the right dicing tape depends on your process requirements:

.For advanced processes or when cleanliness is critical, UV film is preferred.

.For cost-sensitive, simpler cutting tasks, blue film is suitable.

Proper selection of dicing tape improves wafer integrity, reduces chip loss, and enhances manufacturing efficiency.